Job Responsibilities

Due to the sensitive natures of this work, only basic overviews will be provided.

Lead Manufacturing Engineer

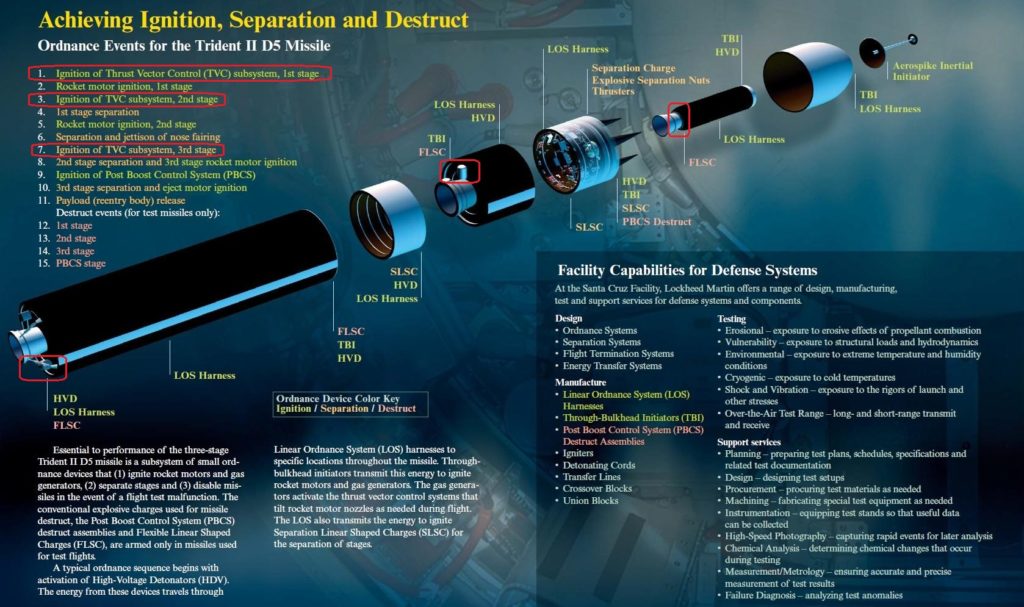

D5 Trident II Rocket Motors (FS, SS, TS)

Objective: To supervise and qualify all processes, internal documentation and associated specifications for the D5 Trident II manufacturing line with anticipation for continuous production through year 2080.

Lead Manufacturing Engineer

Harpoon Anti-Ship Missile

Objective: Supervise and update procedures to ensure efficient and continuous production of Harpoon missiles.

- Streamline manufacturing operations, updating affected documentation.

- Improve ERP system reliability by capturing and incorporating production data for all future batches to utilize.

- Develop and qualify an autonomous chemical spray rig machine for time-intensive and quality-critical washcoat operation.

Support Manufacturing Engineer

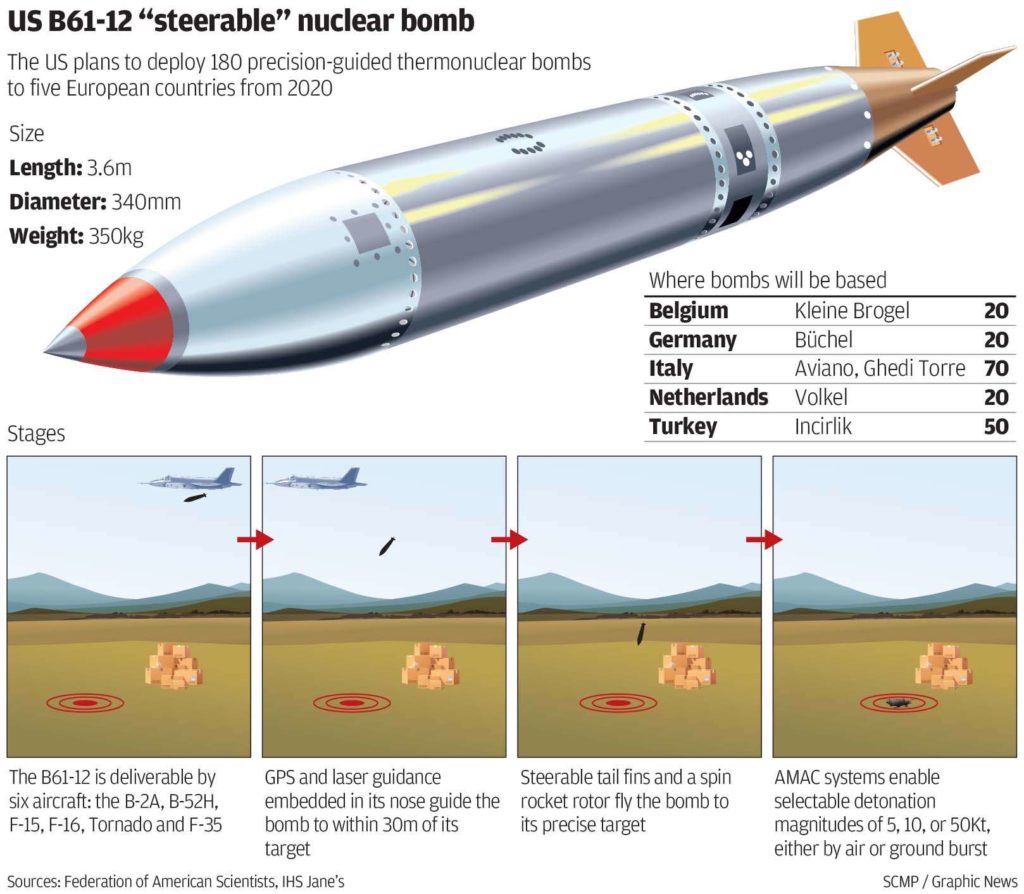

B61-12 (SPIN Rocket Motor)

Objective: Assist in the process re-establishment, manufacturing supervision and associated developmental efforts with frequent customer visitations in anticipation for manufacturing line qualification.

Other Notable Contributions

- Propellant Disposal Engineer

- Design, document and supervise the safe disassembly/disposal of miscellaneous explosive assemblies.

- Organized & documented the safe disposal of:

- Old cruise missile retained from the 70’s with limited drawings, little build knowledge and no remaining tooling

- Legacy STAR motors with slumped propellant from old storage magazines

- Various igniters

- Leading departmental training sessions rolling out new software.

- Emphasize concepts of traceability, reducing schedule/cost impact, and improving quality reassurance.

- Generate systematic solutions to increase plantwide MMAS score

- Drive the plant into the generation of digital documentation by leading the plant’s first live electronic line/mix/cast propellant batch ever (D5 program). Achieved by organizing and delivering frequent inter-departmental software training/support, designing electronic building hardware solutions with OPS, and establishing software standards to be later reflected in internal training and policies.